Walker Design Project

Collaborative design and prototyping of a blade-based conduit cutter for Atkore, integrated into a walking machine platform.

Project Overview

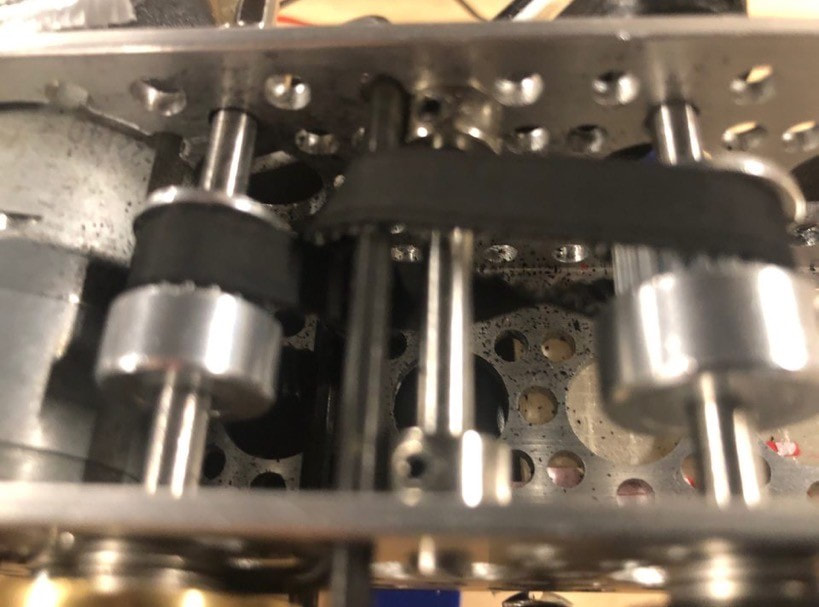

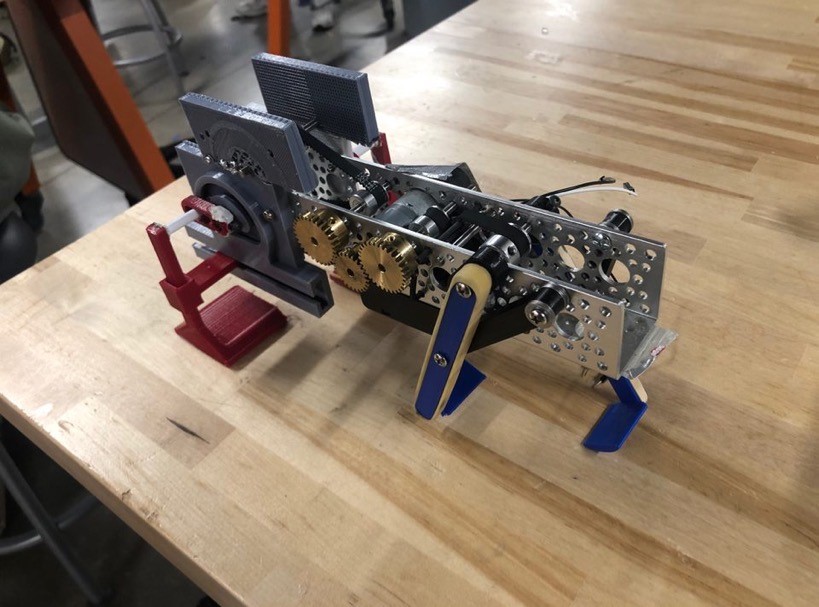

This project involved designing, prototyping, and optimizing a compact walking machine with a multi-linkage leg system. The core challenge was to integrate mechanical and motor systems that met the following constraints:

• Two legs must use 4-bar linkage mechanisms

• Two legs must be actuated via cam-based linkages

• All four legs powered by a single electric motor using belts, gears, or chains

• Entire walker must fit within a 30 cm³ cube

• Demonstrate understanding of mechanical optimization and design principles from coursework

• Two legs must use 4-bar linkage mechanisms

• Two legs must be actuated via cam-based linkages

• All four legs powered by a single electric motor using belts, gears, or chains

• Entire walker must fit within a 30 cm³ cube

• Demonstrate understanding of mechanical optimization and design principles from coursework

We explored various linkage geometries through CAD modeling, laser cutting, and 3D printing. Designs were iteratively refined to improve balance, motion repeatability, and torque distribution across all four legs.

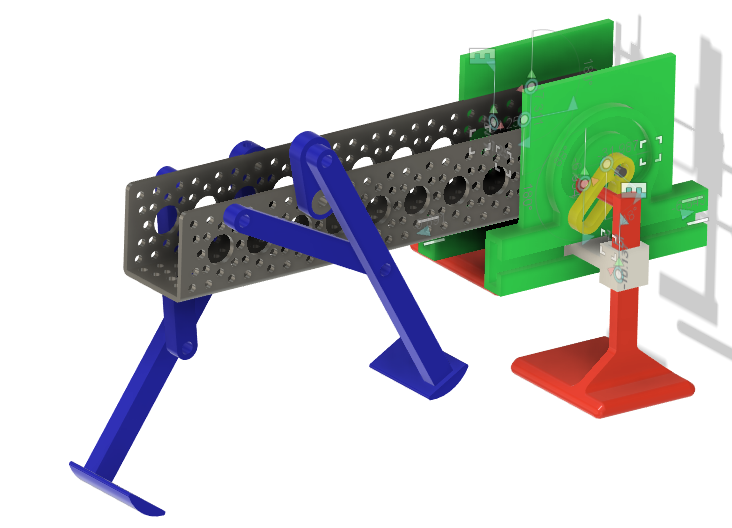

Simulation Showcase

Demonstration of the final walk cycle, showing coordinated leg movement powered by the motor system.

Final Outcome

The walker met all design constraints, traveled over 8 meters during testing, and reflected a deep understanding of mechanical kinematics. The project highlighted the importance of balancing theoretical optimization with real-world prototyping.